Vehicle teardown expert Sandy Munro and his team at Munro & Associates have got their hands on a Giga Texas-made Model Y recently. The specialty of these specific Model Y electric SUVs is that they have the latest 4680 form factor cells, structural battery pack, and both the front and rear underbody Giga Castings.

Munro and his team of highly qualified and skilled engineers are working hard to unveil the secrets behind all the new developments to these specific Model Y features.

In the most recent video (below), Munro’s team tried to remove the top metal cover of the Model Y structural battery and they found that it was glued too hard to the pack using a Polyurethane (PET) adhesive. Corey Steuben President of Munro & Associates said that this pack is very rigid and good from a safety standpoint but has zero repairability.

Removal of the Model Y Structural Battery

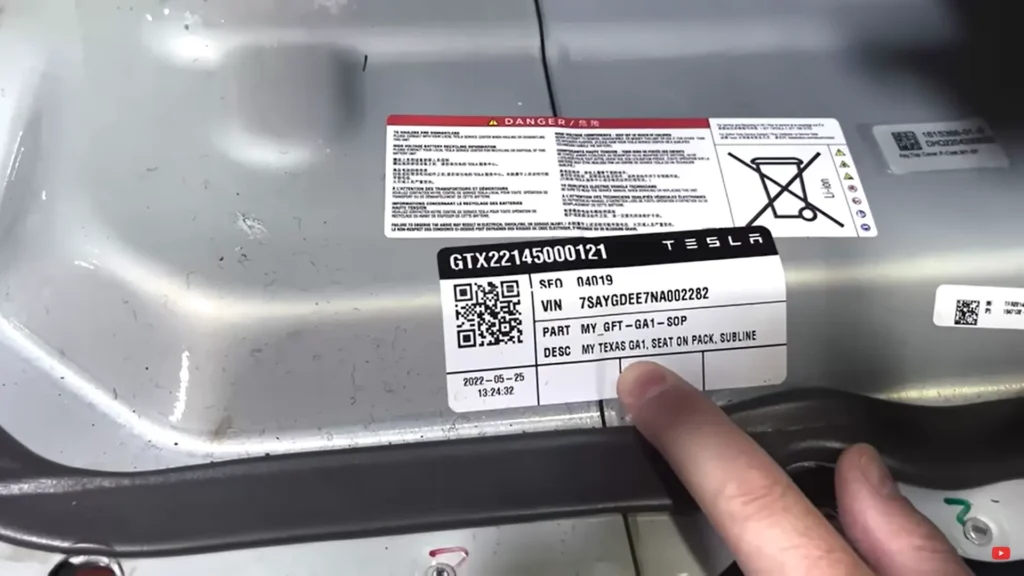

The team at Munro was successful at removing the structural battery pack from the Giga Texas-made Model Y earlier this month. It was actually an easy process as it only had 38 bolts that hold the pack to the body.

The front seats of the Model Y are actually mounted to the structural battery pack as the automaker showed them at Giga Berlin Giga Fest. There was no change in this setup when the vehicle went to production.

Corey explains the cover of the Model Y structural pack as “a multi-piece tailor-welded blank design”. The steel cover is relatively thinner in places and thicker where the seats are mounted and heightened. The thick metal is used in specific areas of the pack to support the weight of the seats, center console, and the humans while driving.

Let’s watch how the Model Y structural battery was removed from the car along with the front seats and the center console and more explained by Munro engineers.

Hard Metal Cover Removal

As the engineers uninstalled the seats from the Model Y structural battery, the next task was the removal of the steel cover of the pack. This is where the team has been stuck for days as the metal cover is too rigid and is pasted with a very hard polyurethane adhesive.

This Polyethylene Terephthalate (PET) is also very durable as Corey explains during the short video on why Munro & Associates have not yet been able to get their hands on the 4680 cells. This cover is very difficult to remove.

Due to this super hard attachment of the steel cover to the battery pack, this structural battery is virtually impossible to repair, Corey explains.

Munro plans to sell individual Tesla 4680 cells as they get them out of the battery pack, so getting a reservation in advance would be good to get your hands on one by going to MunroLive.com online store (the price is $800 for a 4680 cell, limited availability).

Related

- Model Y Performance starts appearing in Tesla showrooms in the US

- Tesla Robotaxi spotted validation testing in Pennsylvania ahead of service expansion

- Tesla update 2025.38.9 goes wide release on HW3 cars and the Cybertruck (skipping FSD v14)

- Here’s how to get your free Tesla Ride (FSD Experience) in the United States

- Tesla shares the new Model Y Performance design philosophy

- Tesla (TSLA) launches the 2026 Model Y Standard in Europe with a 534 km range