Vehicle teardown expert Sandy Munro and his team go even more in-depth to study the Tesla Model S Plaid battery pack, its cell structure, formation, thermal management, and more. Munro posted a video detailing how Tesla achieved an optimal power disbursement solution to make the Model S Plaid the quickest production car ever made.

Sandy Munro’s engineering firm Munro & Associates bought a Tesla Model S Plaid in December last year. He and his team first extensively test drove it for thousands of miles for performance and reliability assessment.

Later on, earlier this year, Munro started the teardown of the Model S Plaid, the engineering stuff he and his team are best at. The battery pack of Munro’s Tesla Model S Plaid was disassembled in February and we got a detailed analysis of its components and features.

It’s configured for speed

Sandy Munro on Tesla Model S Plaid battery

In this next phase of the Plaid battery teardown, Sandy Munro & Corey Steuben President of Munro & Associates presented their findings on the cell structure, its electrical and electronic components.

Munro also explained why Tesla built the new design refresh Model S/X battery pack the way it is built and why the setup is a bit different from Model 3 and Model Y.

This analysis is particularly interesting because Munro placed the Model S Plaid and Model Y battery packs side-by-side to explain the differences and comparisons between both. Model S and X battery packs are the same and Model Y and Model 3 packs are the same, so anything explained in this analysis will apply to the not-so-discussed ones as well.

Since it’s a detailed analysis, we have broken it down into segments for better understanding and explanation.

Table of Contents:

- Battery Modules and Cell Formation

- Cell Formation and the Use of 18650 Form Factor

- Cell Orientation

- Thermal Management / Cooling System

- Battery Management System (BMS)

- Verdict

Battery Modules and Cell Formation

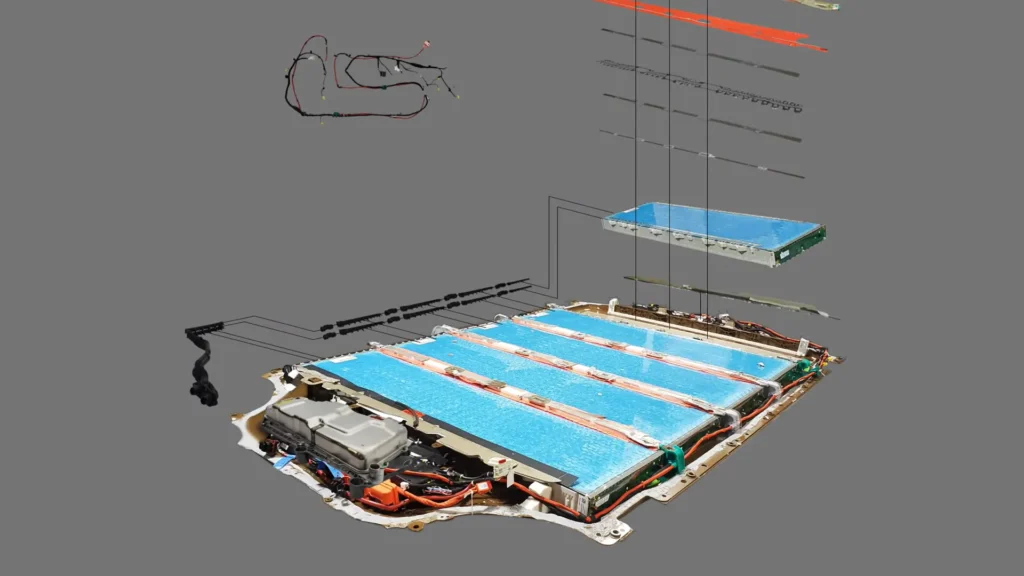

The layout of the Model S and Model X battery pack modules is different from Model 3 and Model Y. For Model S/X Tesla has chosen the horizontal layout (same as the direction of the seats, see Fig 1 below) while the Model 3/Y modules are laid out in a longitudinal direction (vertically across the vehicle from the front towards the rear).

Tesla Model S Plaid battery pack has a total of 5 modules or cell bricks. Each module has 22 rows (series) of cells and each row has 72 cells in parallel. So the total number of cells in each module is 1,584 (22 x 72).

Since there are 5 modules in a Tesla Model S Plaid battery pack and all of them are of the same length and width, the total number of cells in it is 7,920 (5 x 1,5784).

There are more than 16,000 welds in a Tesla Model S Plaid battery pack (all 5 modules) as Munro and his team physically and literally counted them. Each cell has 2 welds and there are 7,920 cells, that alone gives us 14,580 welds. There are other laser welds where an aluminum jumper connects all 5 modules (see video below).

If one of these 14,580 welds fails, it’s going to disconnect a single cell which will only wipe out 1.39% of power/current from the system. In his life spent in engineering, Sandy Munro says that laser welds almost never fail.

Electrical tests showed that a single module produces 80-82 volts, so all 5 modules or the entire Model S Plaid battery pack produces 400-410 volts.

Use of the 18650 Form Factor Cells

Back in 2020, Tesla CEO Elon Musk said that the new Model S Plaid will have 4680 cells and the structural battery pack — but due to COVID, supply chain issues, and the dire need to start production, his thoughts didn’t materialize.

Tesla kept the old smaller 18650 form factor cells for the new Model S and Model X. This selection enabled Tesla to start production and deliveries of the Model S Plaid without compromising on the power and speed of the vehicle.

Tesla is currently only manufacturing Model Y electric SUVs with 4680 cells and the structural battery pack at its Gigafactory Texas plant. No other Tesla Gigafactory is yet ready to implement 4680s in its cars — the main reason is not having enough cells that Tesla makes themselves or provided by Panasonic as of now.

Cell Orientation

One difference between the Model S/X and Model Y/3 battery modules is the orientation of the cells. In Model Y/3, all the cells are placed in the same orientation/direction (all + sides in one direction and – sides in one).

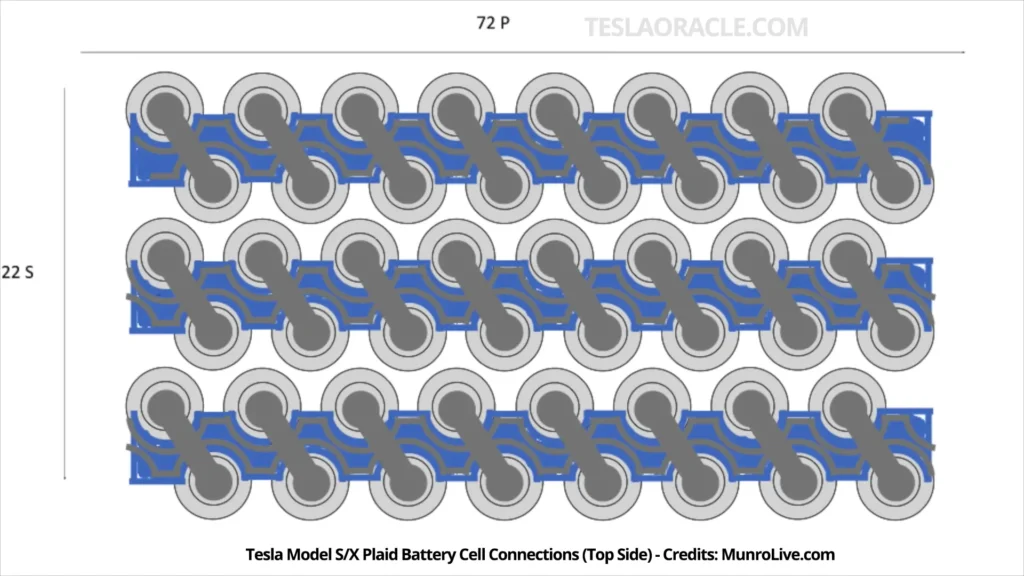

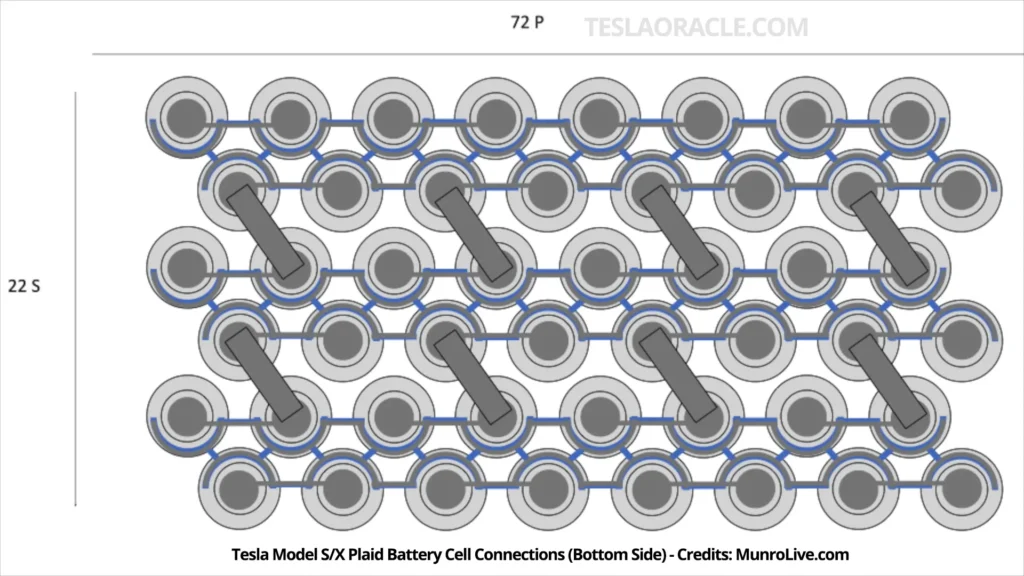

But Tesla has used alternate orientation in Model S/X and their Plaid variant battery modules. One row has all the plus (+) sides on one side and the next row has all the minus (-) sides of the cells on the other side (22 rows, 2 rows in a plus/minus group, 11 groups per module).

This alternate orientation allows for making connections between the upper and lower rows. Tesla is using aluminum strips and laser welding to connect the cell groups together (see Fig 2 & 3 below).

Despite the different cell orientations, Munro says that this is a much simpler design than what was in the original Model S/X. These early Model S/X vehicles had between 12/16 modules/bricks of cells and the battery pack’s center spine was a structural piece, Munro revealed.

Sandy Munro also revealed a historical fact that it’s not totally true that Munro & Associates never worked for Tesla. When the first Model S came out Tesla had trouble automating this alternative cell orientation pattern and the pack’s assembly — a member of Munro’s team named Tim Shaw went to Tesla to help them out with this challenge (probably around 2012).

According to Corey, Tesla also struggled with the quality of the cell connections along with temperature and voltage morning for the early Model S battery pack because of the large number of modules and their somewhat random setting.

Thermal Management / Cooling Systems

The 1,020 hp Tesla Model S Plaid is most probably the most powerful family sedan in the world. This much power needs an efficient cooling system when the batteries get super hot, especially in drag racing / launch mode.

This much power generation generates a lot of heat and Plaid needs to wick-away heat fast enough to save the systems from getting damaged. One solution added in 2021 onwards Model S/X refresh vehicles is the addition of the heat pump and the newly-designed radiator.

Tesla has implemented even more strategies to wick-away heat (as Sandy Munro calls it, wicking literally means “acting to absorb or draw off liquid by capillary action”).

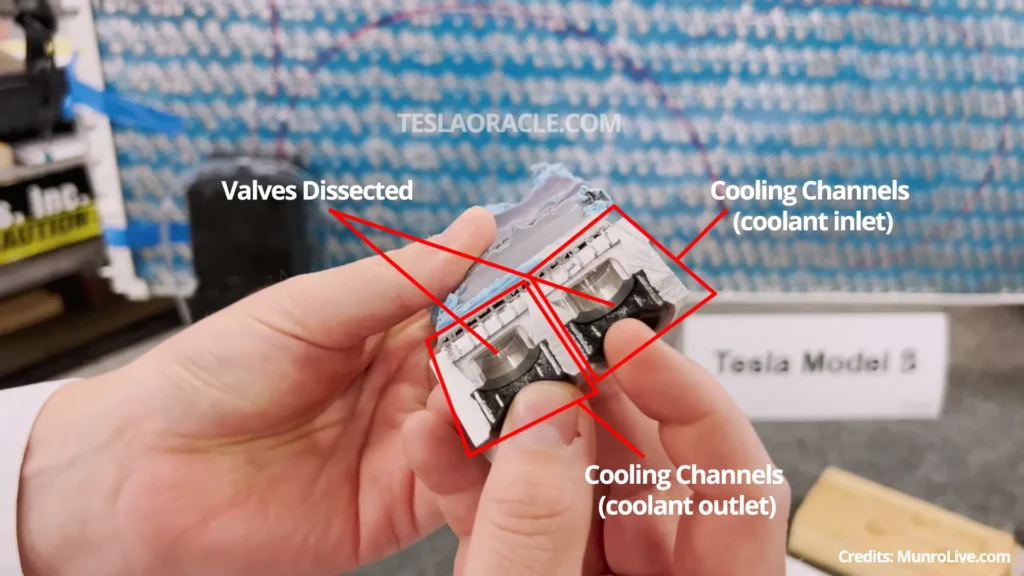

Liquid coolant flows two ways (in/out, see Fig 4 below) in a single cooling channel of the Model S Plaid battery, it’s the same width as the height of the 18650 cells (i.e 65 mm / 2.559055 inches). Each cell is wrapped in gray Polyethylene Terephthalate (PET) coating and pasted onto the cooling channel using an adhesive, then each row is covered in thick hard foam, even more so between the group of rows.

“It’s got great cooling, why not keep it the way it is,” Sandy Munro said about Tesla still keeping the 18650 cells for the latest generation of Model S and Model X vehicles.

Battery Management System (BMS)

There is a Battery Management System (BMS) circuit for each of the 5 modules in a Tesla Model S / Model S Plaid battery pack. And each BMS circuit has 2 temperature sensors to monitor the cooling system. These sensors are called Negative Temperature Coefficient (NTC) thermisters.

There used to be 6 thermisters on a Tesla Model 3 BMS (the older model that Sandy Munro tore down) that Tesla later on reduced to only 2 for the Model Y and 2 sensors is what Tesla continued with the new Model S/X refresh. Each BMS is connected through 22 connectors connected to each row of cells in a battery module (see Fig 5 below).

A BMS has several other functions related to a battery’s health and efficiency as well but since we’re discussing this in the context of thermal/cooling systems, we will restrict it to the topic here.

Interestingly, Tesla has a hidden easter egg printed on the Model S Plaid BMS, it says “Tesla, Inc. Made on Earth by Humans”.

Verdict

Sandy Munro closes the analysis by praising Tesla’s precision and engineering excellence that emanates from the Model S Plaid battery pack. He says that this level of precision is even beyond 7 Sigma quality level which allows for an error rate 0.0000019% (perfection level of 99.9999981%).

So Tesla is leading the entire automotive industry when it comes to engineering and technological advancement and this battery pack is a living proof of it. Sandy Munro said that he was impressed by Rivian but still it’s not Tesla Model S or even a Model 3.

Munro and his team prepares truly in-depth reports and extensive data as they tear down an electric vehicle and established and new players in this business can benefit from them which are available to buy on MunroLive.com.

Sandy Munro has now set his eyes on the teardown of a Giga Texas-made Tesla Model Y Standard AWD with the 4680 cells, structural battery pack, and front and rear underbody Giga Castings.

We will be coveering that for sure, so stay tuned and let us know your thoughts in the comments section below.

Stay tuned for constant Tesla updates, follow us on:

Google News | Flipboard | X (Twitter) | WhatsApp Channel | RSS (Feedly).

Related

- Tesla engineers reveal Cybertruck secrets to a 5-star crash safety rating by the NHTSA

- Tesla installs two 9,000-ton Cybertruck Giga Presses at Giga Texas, lays the foundation of the 3rd as production nears

- Huge parts of the 9,000-ton Tesla Cybertruck Giga Press arrive at Giga Texas

- Sandy Munro weighs in on the leaked Cybertruck casting image, intends to teardown Tesla Semi

- IDRA’s 9,000-ton Cybertruck Giga Casting machine is on its way to Tesla Giga Texas from Italy

- IDRA unveils the production version of its 9000-ton Tesla Cybertruck Giga Casting machine

How can the loss of one cell out of 7920 possibly account for 1.39% of power?

It’s Sandy and his team’s calculation.

It drops the entire battery pack by it’s capacity out of all pairs. That is, if you have a pack that is 2p 10s (two batteries side by side to double capacity, and ten of those sets stacked to increase voltage) and a single cell were to disconnect, the battery pack would lose 50% of its amp delivering capacity. Weakest link and all that. This would also reflect in total usable amp hour capacity too since the pack would have to take power from the other cells and direct it at the lone wolf in an attempt to keep balance. This would also trigger a limp home condition and limit the speed etc severely with a mandatory repair warning.

1.39% = 1/72 so the the other 21 rows must only charge to the the level of the row that contains the lost cell.

Seems like it would have this impact on only one of the 5 modules.