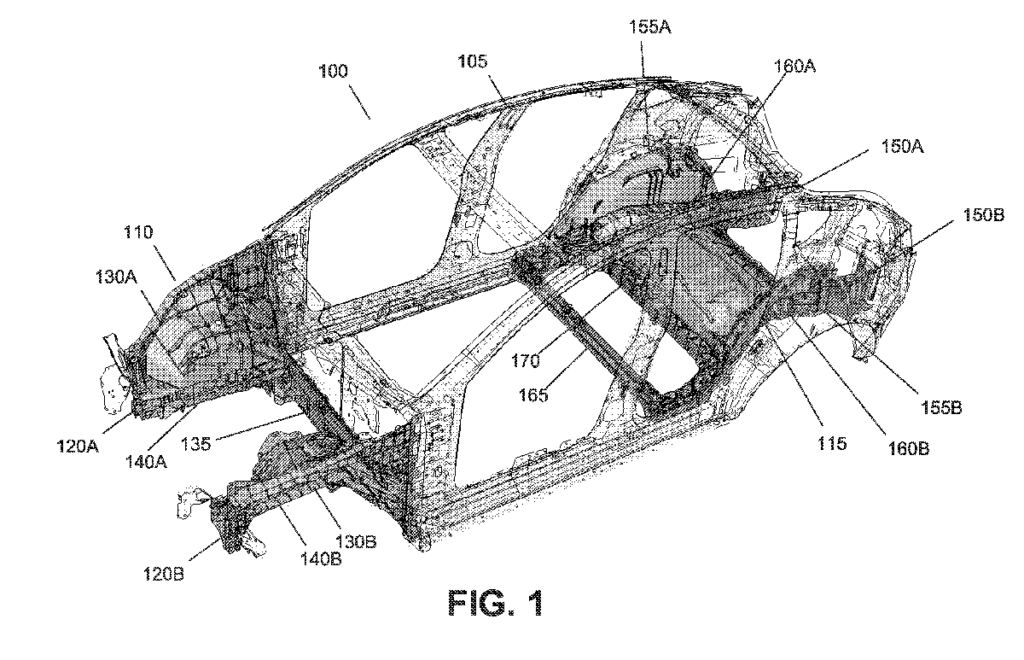

A new international patent filed by Tesla last year was published on the website of the World Intellectual Property Organization (WIPO). This patent publication demonstrates how the front and rear single-piece underbody castings act as integrated energy-absorbing objects — enhancing the safety of a Tesla vehicle.

These large single-piece front and rear castings are also known as Giga Castings among Tesla owners and enthusiasts (the Tesla Community). These castings were initially invented to reduce the number of parts and welds to manufacture these parts.

In the first production versions of Tesla Model 3 cars, the rear underbody was put together by welding around 70 pieces together. This flaw was detected by the vehicle teardown expert Sandy Munro. Elon Musk fired the engineer who was responsible for this blunder and improved the Model 3 rear underbody casting in the later revisions.

On 2020 Battery Day, Tesla CEO Elon Musk revealed the newly developed rear underbody Giga Casting that was integrated into the automaker’s newly-launched Model Y electric SUV at the time. Model Y cars produced at Fremont, USA and Giga Shanghai, China only have the rear underbody single-piece casting. The additional front single-piece underbody casting is only available in Model Ys made at Giga Texas, Giga Berlin, and Giga Shanghai.

The new international patent describing these patents reveals that these front and rear Giga Castings further enhance the safety of any current or future Tesla vehicle equipped with single-piece underbody castings.

The abstract of this patent summarizes the safety perspective of Tesla Giga Castings as:

An integrated energy-absorbing system of a vehicle with a front integrated energy-absorbing casting and a back integrated energy-absorbing casting. Each front and rear casting is a single unified casting that makes up the integrated energy absorbing system. Ribbed sections such as “I” sections and “C” sections make up the castings and are formed from a variety of different techniques and/or formings such as cutout, waveform profile, tapering, flaring, and/or rib spacing. Additional sections such as closed section castings may also be integrated in the integrated energy absorbing system.

WIPO Patent No. WO/2022/031991

Tesla is not the first auto manufacturer to install impact-absorbing systems into a vehicle frame. But designs by traditional automakers are created using multiple parts and also utilize plastics in those systems. Tesla has made these impact-absorbing castings in a single piece each for the front and back underbody.

Tesla explains the difference of their energy-absorbing system compared to the ones made by traditional automotive manufacturers in the description of this patent as follows:

Traditional collision impact energy-absorbing systems for vehicles include a plurality of multi-piece components. For instance, a collision impact energy absorbing system may have multiple connected pieces in the front and rear end of the vehicle that are structured into multiple stages designed to compress or crush in response to an impact force. These multiple stages may include metal stampings or extrusion components which crumple in response to an impact force.

Traditional collision impact energy-absorbing systems mounted to vehicles are unable to support the increased demand for efficient manufacturing and scalability of design due to their multiple pieces and staged traditional design. Moreover, as the number of components that make up the impact energy absorbing system increase, the complexity and costs associated with manufacturing, installing, and servicing these traditional impact energy-absorbing systems becomes excessive.

WIPO Patent No. WO/2022/031991. Read the full PDF below.

Not to forget that Tesla Model Y has already scored 5-stars in the NHTSA crash safety ratings and even outperformed Tesla Model 3 in the IIHS crash tests. Another layer of safety with these impact energy-absorbing unitary castings surely will enhance the safety of this vehicle even further.

Tesla has proved again and again that it practices the continuous improvement ideology across the board. If this system is present in Model Y today, it will surely transition to the rest of the vehicle lineup in the coming years as safety is the utmost priority of the automaker.

Related: Watch the Model Y casting machine in action at Tesla Fremont factory

Stay tuned for constant Tesla updates, follow us on:

Google News | Flipboard | X (Twitter) | WhatsApp Channel | RSS (Feedly).

very insightful and remarkable engineering done. It is highly aimed to make vehicle structures provide increased safety. Good luck!

Very insightful article. The new engineering design will surely enhance the passenger safety in an event of crashing. Good luck!

Bonjour merci d’avance de bien vouloir me tenir informer de la date de fabrication du modèle Y Long Rang dans la Gigafactory de Berlin

Ce modèle possèdera t’il la batterie 4680?

Cordialement

Mr Eloy

Yes, It will have the 4680 cells as revealed during the Giga Berlin Giga Fest