Vehicle tear-down analysis expert and now a well-known personality in the world of Tesla and Elon Musk, Sandy Munro advances his study on Tesla’s 4680 cells and the new battery pack.

After Tesla Battery Day, he took a deep dive into the 4680 cells and the new battery pack back in September. In his latest video on this topic, he has shared more of his findings and presented some clarifications during his research (video below).

Days of Modules & Bricks in a Tesla Battery Pack are over

With the advent of the 4680 cell form factor, the need for modules and bricks in a Tesla battery pack has been eliminated, Sandy Munro emphasizes. He says that this has been a repeated question about the next-gen Tesla battery pack.

Using the 2170 form factor, a Model 3 or Model Y Long Range battery pack had to contain 4,416 cells. With the new 4680 cells, this number has reduced to only 960 cells in the same space and the battery capacity would jump from ~74kWh to ~130 kWh. According to Munro’s calculations, the battery pack size can be reduced by ~40% to achieve the current battery capacities in Tesla vehicles.

How this defies the laws of Physics to give the Tesla Semi a 621 miles (~1000 km) range, perhaps Head of Daimler Trucks need to re-think his statement one more time.

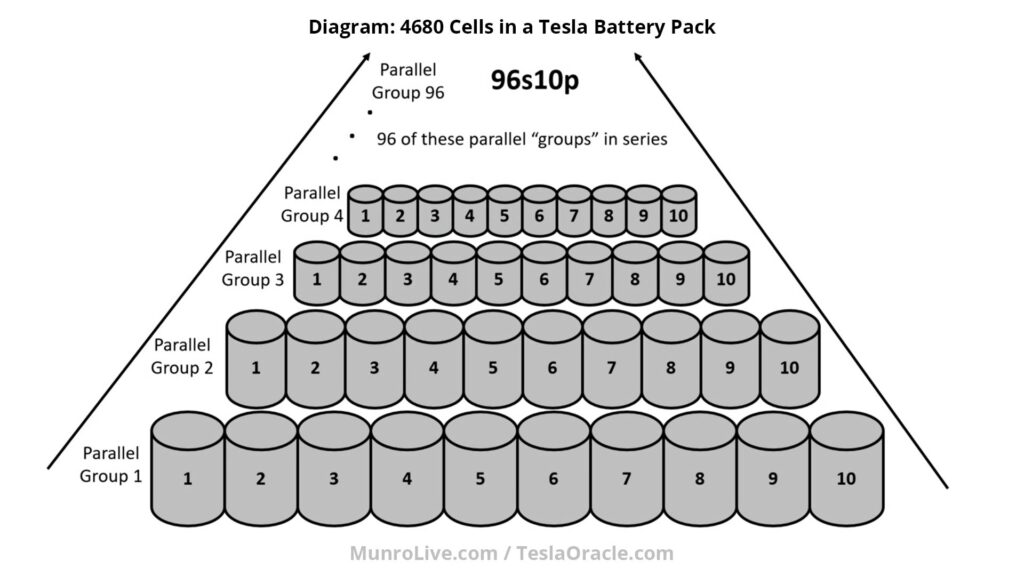

Since the cells will be soldered in parallel, Sandy Munro calls each line a group of cells. With 10 cells in a single row (group), there will be a total of 96 groups in a Model 3 / Model Y Super Long Range battery pack. Tesla might eventually reduce the size of the pack to bring the battery capacity of these smaller Teslas to under 100 kWh (see Diagram 1 below).

The ‘Tab-less’ confusion

Sandy Munro further clarifies the confusion surrounding the tab-less-ness of the 4680 cells. He says that the tabs are inside the battery and not being on the top/bottom on the outside, doesn’t affect the output power of the battery cells.

He displays the dummy cells he has made with the same 46 mm x 80 mm form factor with a thumb pin inserted into the cathode side to mimic the transfer of electrons out of the cell, pretty neat in my opinion.

Thermal Management

In response to questions from some scientific minds, he admitted that heat rises. In his opinion though, Tesla would solve this using a cooling plate at the bottom of the battery pack, he extrapolated this by presenting the Model Y Octovalve that has a heat-sink plate welded under the entire structure.

This is called ‘conduction’ — Munro even thinks that Tesla will also put some sort of cooling liquid or material under this cooling plate to more efficiently absorb the heat generated from the battery cells.

Tesla’s Giant Advantage

Sandy Munro took the example of the Chevy Bolt’s cooling or heat management system. From the 1st time the Bolt EV was launched, it has the same cooling system, and Sandy thinks that it’s not going to change. This has much to do with an organization’s culture and compliance with ‘continuous improvement (Deming Cycle)‘, traditional automakers don’t practice that.

Tesla on the other hand has already transitioned the Model Y heat pump to the 2021 Tesla Model 3 — innovation just doesn’t happen in concept presentations at Tesla, it actually is applied as soon as possible.

Follow us to stay tuned for more interesting Tesla stuff:

Google News | Flipboard | RSS (Feedly).

A change from 4416 2170 cells to 960 4680 cells is not an increase from an 81 kWh pack to a 130 kWh pack.

Here is the current breakdown of the 2021 Model 3 battery pack, with each cell containing 3.7 nominal volts with 5 aH of energy:

4416 × 3.7 × 5 = 81,696

Since the 4680 has a quoted 5x energy increase, equal to 25 Ah in each cell, and there will be 960 cells, this means:

960 × 3.7 × 25 = 88,800

The redesigned packless battery would be 88.8 kWh, max, not 130 kWh, equal to a final increase of 8.7% in capacity over the current 2021 Model 3 and Y. This means once the new pack designs are complete, the Model 3 and Y will have ranges of approximately 383 miles and 354 miles, respectively.