A toast was celebrated at the battery assembly company in Neuwied/Germany named ATW. This became possible because Tesla came to its rescue when the firm lost contracts with key automotive clients Daimler and BMW.

According to a local newspaper Rhein Zeitung’s website, negotiations between Tesla and ATW began in early September and now the acquisition is in its final stages. This acquisition will save the jobs of 210 existing ATW employees and the growth of the company in the near future is highly likely to escalate as it will not have to look for new business anymore. Assembling battery packs for Tesla will be the only business requiring the allocation of all the company resources to it.

ATW is a subsidiary f the Canadian automation engineering firm ATS (Automation Tooling Systems Inc. ATA/TSE). A press-release by ATS from late September says the following about this deal:

Cambridge, Ontario (September 25, 2020): ATS Automation Tooling Systems Inc. (TSX:ATA) (“ATS” or the “Company”), an industry-leading automation solutions provider, today announced that as part of its previously announced plan to reorganize its Transportation business, it has entered into a conditional agreement to sell certain assets and transfer employees of one of its German-based subsidiaries to a third party.

Completion of the sale is subject to several closing conditions. If the transaction does close, it is expected to partially mitigate costs of the previously announced reorganization of its transportation business. Financial terms of the transaction have not been disclosed.

ATS press release

But according to the German news magazine The European, the deal is almost final and the acquisition is very imminent.

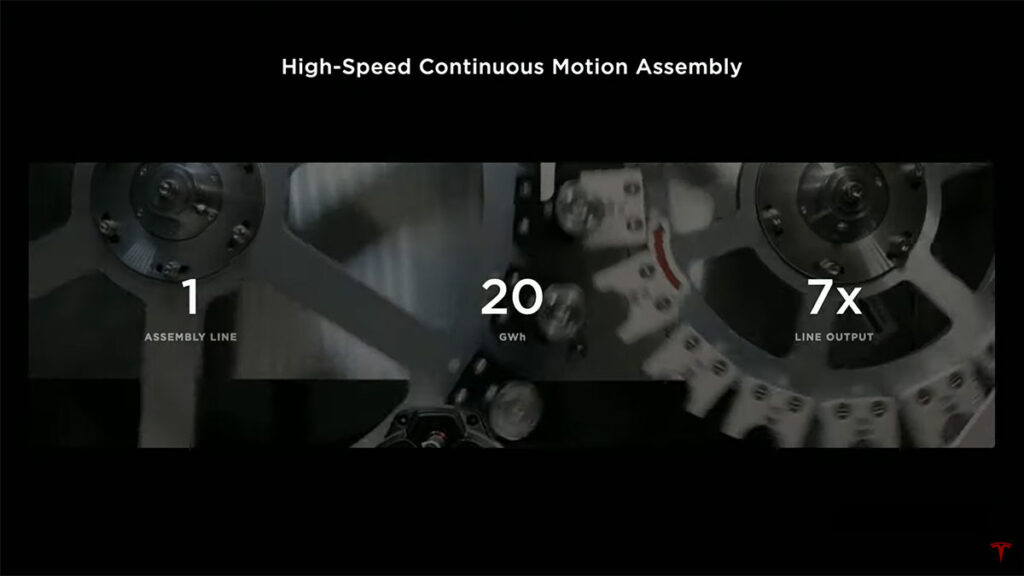

In the Battery Day presentation, Tesla CEO Elon Musk and SVP Powertrain and Energy Engineering Drew Baglino showed the new 4680 cell assembly line at the Tesla Fremont factory. This new pilot project is a large testbed of a high-speed continuous motion assembly line. This philosophy comes from the high-speed bottle manufacturing seen in the beverage industry.

The experience gained at the Tesla Fremont factory’s beta-cell manufacturing can be transferred to ATW’s already skilled engineers at battery assembly automation. This will enable Tesla to locally assemble battery packs in Germany for cars made a the Gigafactory Berlin next year, resulting in even faster car production and deliveries.

ATW is the third in a series of German engineering firm acquisitions by Tesla. The first one was Grohman Engineering GmbH in 2017 which later became Tesla Grohman Automation GmbH.

The 2nd company was last year’s Tesla acquisition of Maxwell Technologies GmbH that is in existing since 1903 involved in ultracapacitor and supercapacitor R&D and production.

Coupled with the new battery technology research unveiled at Battery Day, the acquisition of ATW’s talent pool and skills will definitely an edge to Tesla over competitors in the European electric vehicle market.

With the giant Giga Casting machines planned at Giga Berlin and 7x faster 4680 cell production, the Tesla Model Y production in Germany should worry the local automotive giants like VW, BMW, and Daimler — perhaps they are worried but trying to portray all is well — but it isn’t for them.

Stay tuned for more, follow us on Google News | Flipboard | RSS (Feedly).

- Tesla rolls out the 2025 Holiday Update (2025.44.25.1), new features and release notes

- Tesla FSD v14.2.1 conquers ‘The Snake’ highway in California (hairpin turns, ~30 curves, video)

- Tesla FSD v14.2.1 recognizes hand gestures and proceeds a red light and more (videos)

- License Tesla FSD or face the disruption — Musk once again warns legacy automakers

- Tesla offers 30-day FSD v14 trials to HW4 vehicles in North America, FSD v14.2 goes wide release

- Tesla update 2025.44 goes wide with Radio Traffic Announcements, dashcam tweaks, preps for Holiday Update (Release Notes)