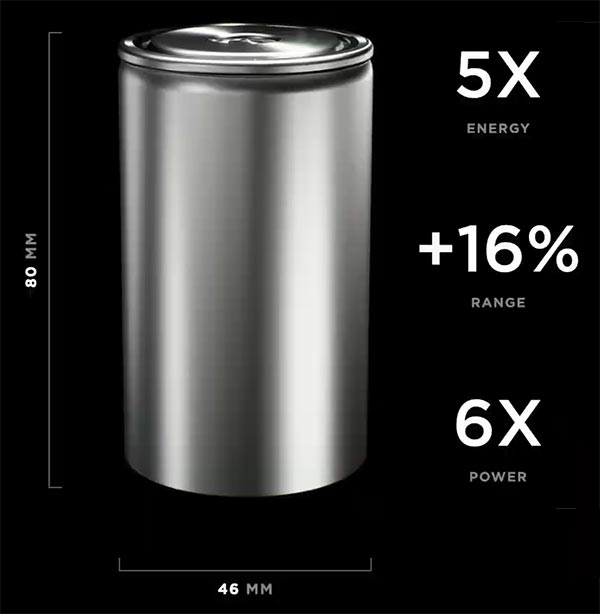

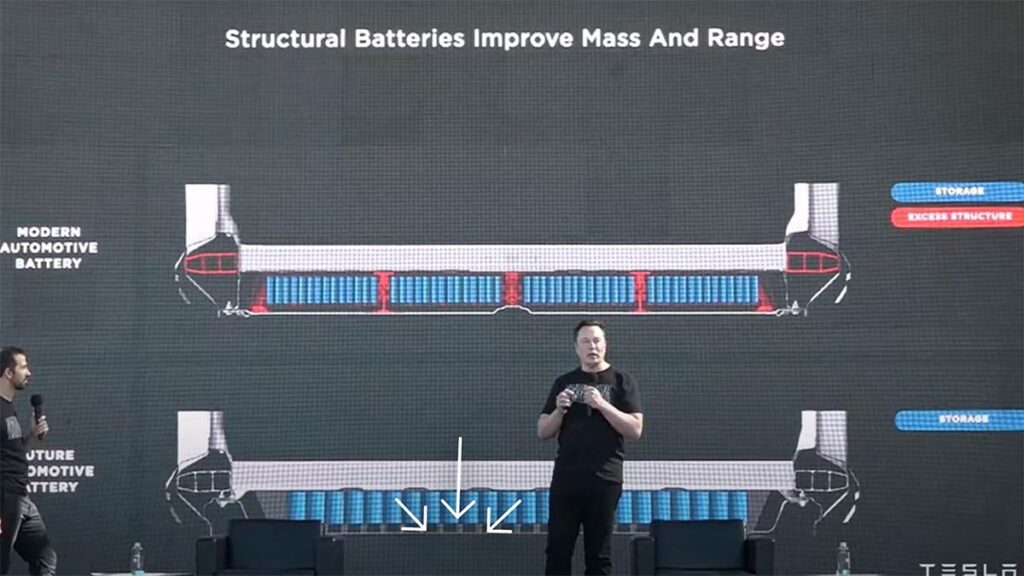

Tesla CEO Elon Musk showed the road to 56% cheaper batteries in the near future. This would be achieved with Tesla’s breakthrough innovations in cell chemistry and materials, simplifying and speeding up the cell manufacturing processes, a structural battery, and the new 4680 form factor.

4680 cell-based battery architecture

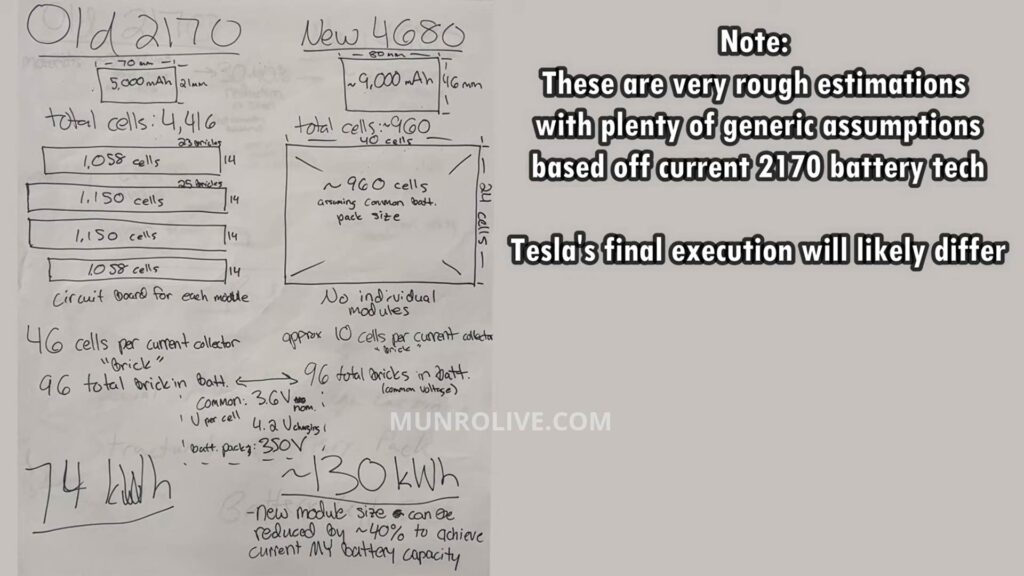

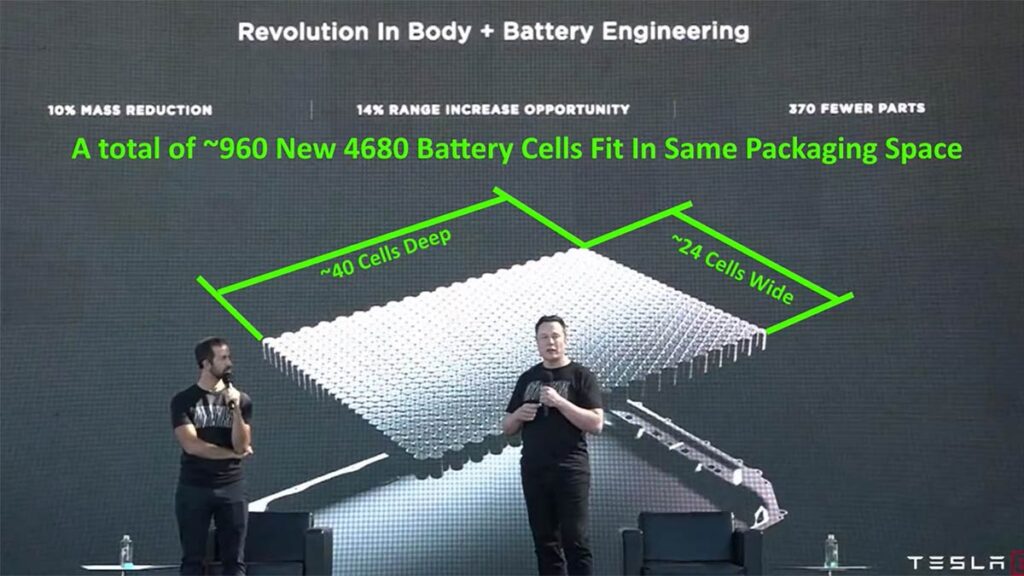

Vehicle teardown expert Sandy Munro has further analyzed how much this new cell form factor can help Tesla achieve its battery goals. According to his calculations, in the same space of the current 74 kWh Tesla Model Y battery pack, a 130 kWh battery can be accommodated — that’s about double the energy storage.

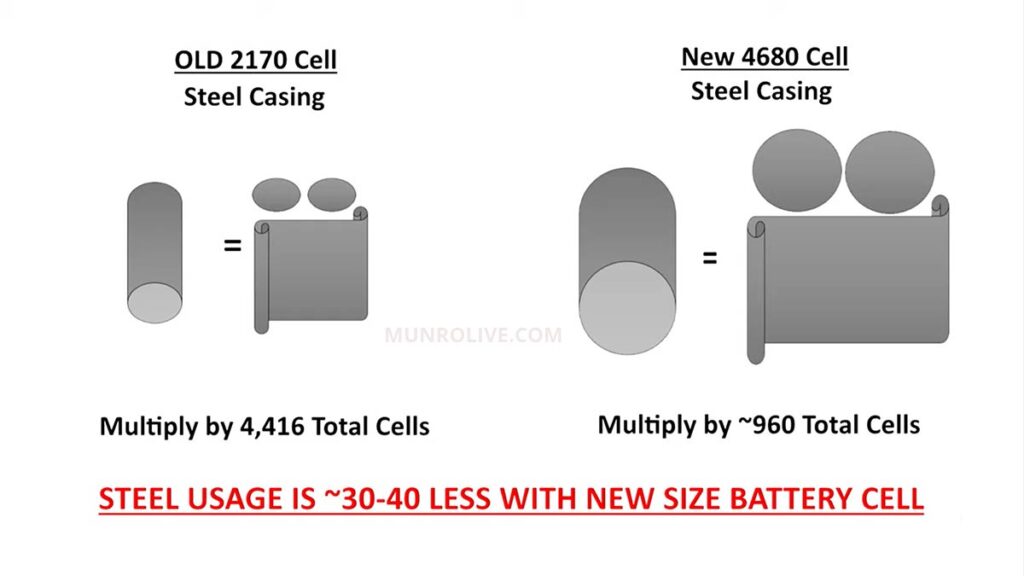

2170 cell is 5000 mAh and Munro’s analysis says the 4680 new Tesla cell will be around ~9000 mAH. Currently, 4,416 (2170) cells are placed inside a Tesla Model 3 and Model Y Long-Range battery packs, there will only be 960 cells required to fill the same space (see Fig 2 above).

The 4680 cell-based battery pack will be much simpler and cheaper to build. The 2170 based battery pack architecture is made of cells divided into 4 modules and further into bricks of 46 cells each and every module requires is own controller circuit.

This complexity will be eliminated by using the new 4680 cell design and coupled with the tabless cell construction, the manufacturing process becomes even simpler requiring fewer parts.

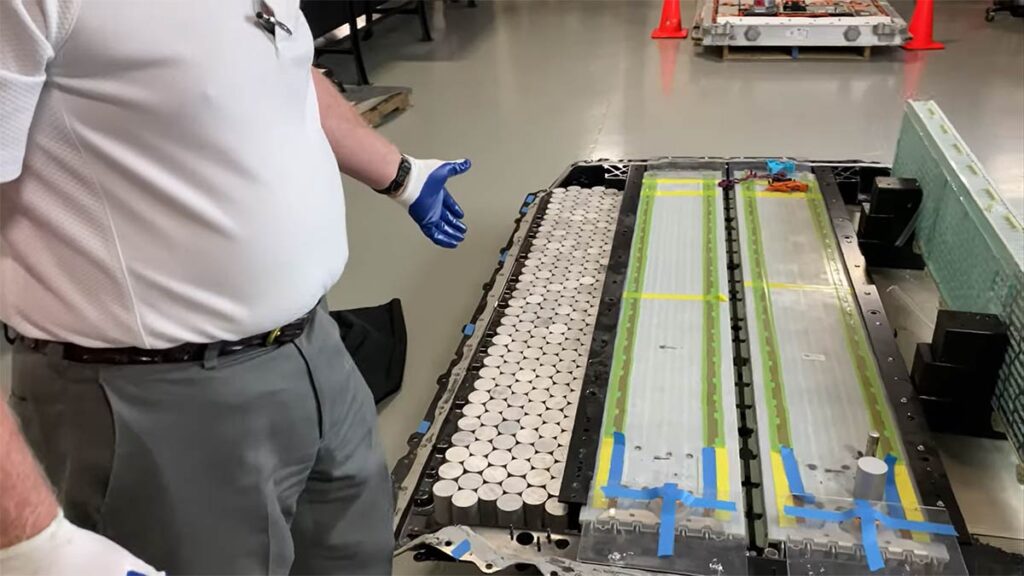

Sandy Munro even showed one of the Model Y module spaces filled with his 4680 dummy cells which he predicted before the Battery Day, a pretty close idea and the size estimate (see Fig 4).

Related: Battery Day Part 1 (Giga Castings & Structural Battery) | Battery Day Part 2: The event in pictures

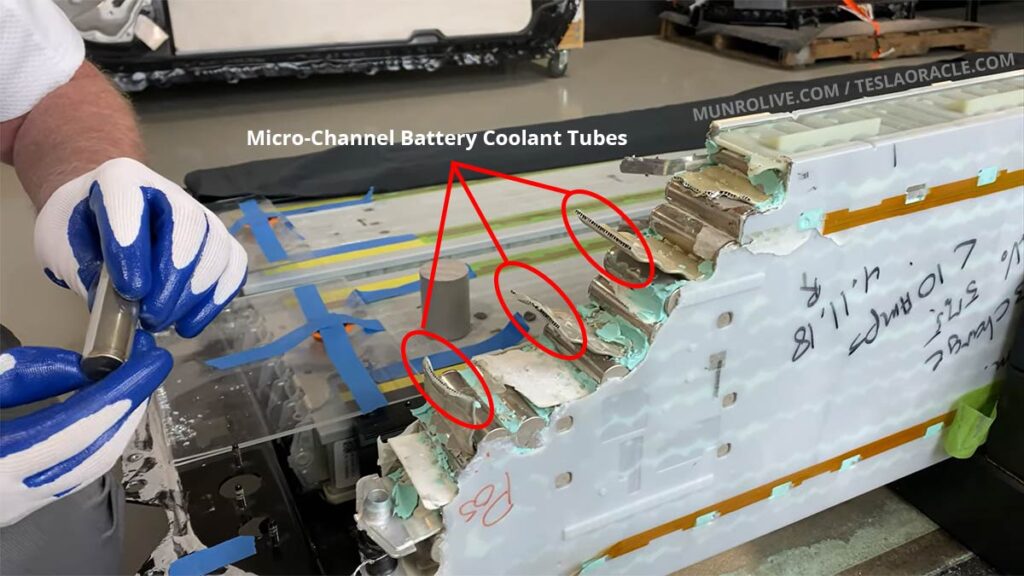

Improved battery cooling

During the Battery Day presentation, Elon Musk presented a slide that shows the dissection of the 2170 vs. 4680 battery pack. If we look closely (see Fig 6 below), the cooling tubes we see in Fig 5 above are at the bottom of the battery pack.

According to Sandy Munro, the right way to cool down the batteries is from top and bottom. Currently, in the 2170 battery packs, the cells are cooled from the sides but in the future, Tesla is planning to do it the right way, installing a cooling plate underneath the batteries.

Rigidity & safety

Tesla Structural Battery with new formation of the 4680 cells will be as rigid as a brick you could ever imagine, says Sandy Munro. With single-piece front and rear castings and the structural battery in the middle, Tesla cars will be virtually twist-proof in an accident.

In Elon Musk’s words at the Battery Day event, this formation will reduce the impact of the polar moment of inertia, making Tesla vehicles even safer than they already are.

Weight & cost reductions

Sandy Munro measured the length of the steel case cover of the 2170 battery cells and found out that with a lesser number of 4680 cells, Tesla will alone be able to reduce around 30-40% use of steel in the battery pack (see Fig 7 below).

Another cost and time savings with the usage of new 4680 cells will come from reducing the number of connections between the cells. With a significant number of fewer cells, the new battery pack will require around 1,800 connections compared to the current packs with ~8,800 wire tabs.

Sandy Munro then goes on to praise the brilliant idea of the single-piece front and rear underbody castings. A concept he has been promoting since 2017 but no automaker adopted it except for Tesla.

Stay tuned for more, follow us on Google News | Flipboard | RSS (Feedly).

I think I might be missing something. The 4680 has about 5 times the volume of the 2170, a bit more even. Hence “5x the energy”. Yet 2170 is ~5000 mAh, and the 4680 allegedly ~9000 mAh, which is less than double the energy. Is the voltage of these batteries different?