Finally, the hyped and anticipated Tesla Battery Day has happened and Elon Musk along with his team has unearthed a lot of important information and processes, the automaker has been secretly working on.

Since there is a variety of topics that cannot be covered in a single article, I will be posting a series on each segment of the Battery Day revelations in multiple parts.

Giga Casting (cost and complexity savings)

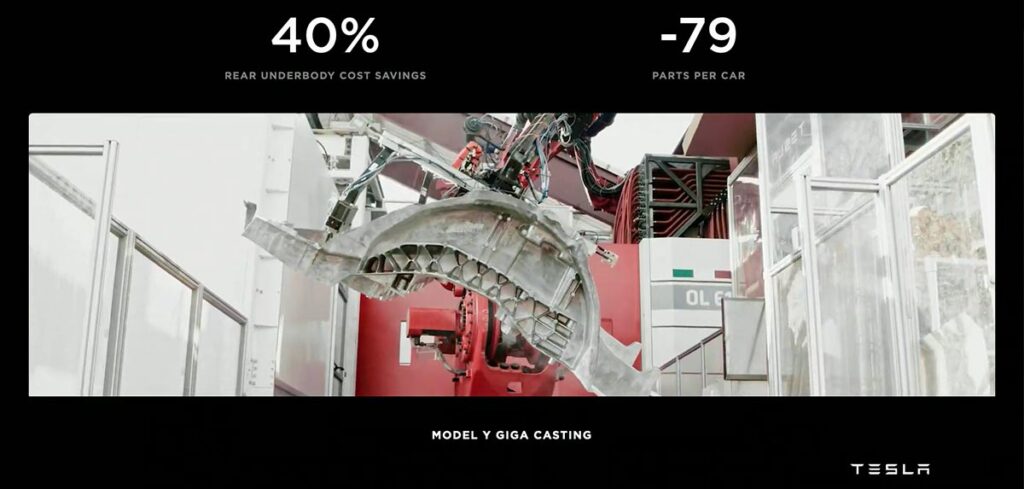

Tesla CEO Elon Musk said that the Giga Casting machine commissioned at the Tesla Fremont factory is the largest casting machine ever been made. His presentation slide (screenshot below) shows that the Model Y rear underbody single-piece casting reduces 40% cost of production and excludes 79 parts in the process.

It’s the way that all electric cars in the future will ultimately be made. It’s the right way to do things.

Elon Musk at the Tesla Battery Day 2020

Reduced manufacturing process complexity and a significant number of fewer parts required is directly proportional to the reduced amount of time needed to produce each car.

On a scale of hundreds of thousands Model Y SUVs produced in 3 continents, would put Tesla years ahead of the competition in terms of speed of manufacturing and customer deliveries.

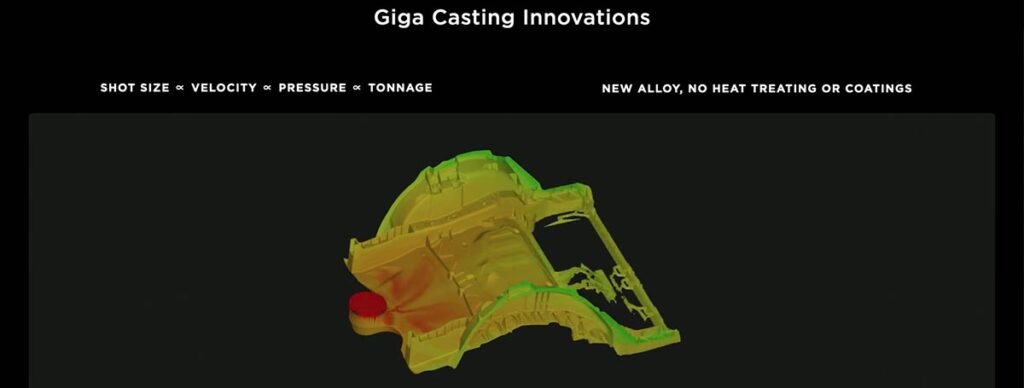

Tesla Developed a Proprietary Alloy for Giga Castings

Tesla has made its own alloy for Tesla Model Y-front and rear underbody Giga Castings. In order to make the entire Model Y rear underbody a single-piece high-pressure diecast aluminum, Tesla had to develop its own high-strength alloy which does not need heat treatment or metal coatings.

In traditional alloys, if you heat treat a large single-piece casting, it starts to deform. According to Elon Musk:

it’s just like the potato chip thing, it’s very hard to keep a large casting to have its shape. So in order to achieve this, there’s no alloy that existed that could do this. So we developed our own alloy, a special alloy of aluminum, that has high strength, without heat treatment, and is very cast-able.

Elon Musk at the Tesla Battery Day 2020

This was only achieved through the hard work of Tesla’s materials engineering team and Elon thanked them on the stage for this (video below). The newly Tesla-developed high-strength aluminum alloy and single-piece Giga Castings will ultimately transition to the rest of the lineup in essence with Tesla’s practice of continuous improvement and innovation.

Structural Battery

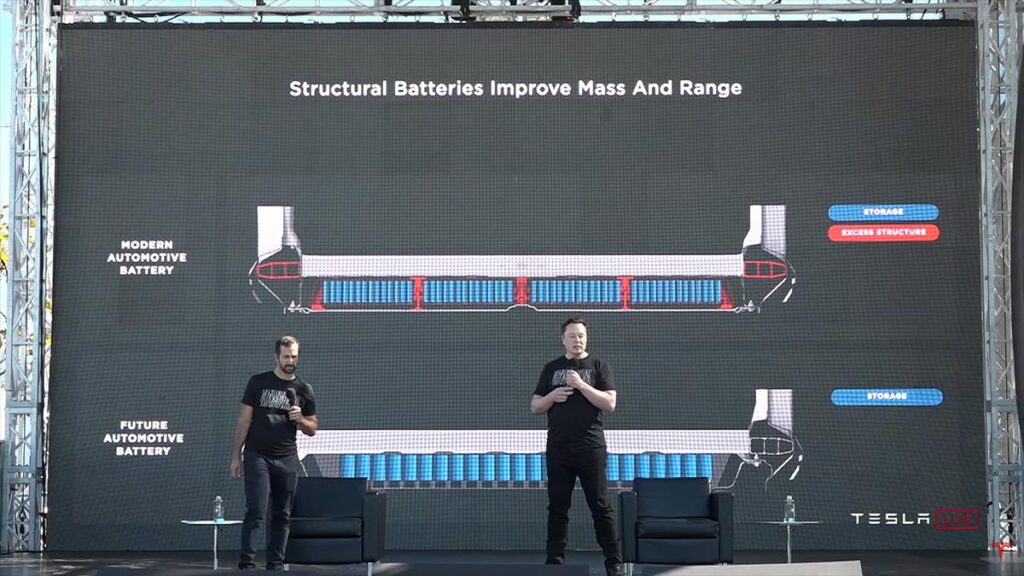

Elon Musk brought another Tesla development to light in his presentation. After the single-piece front and rear castings are made, the battery pack will also now play two roles. One as a source of energy and the other as a structural component that binds and strengthens these two large body castings.

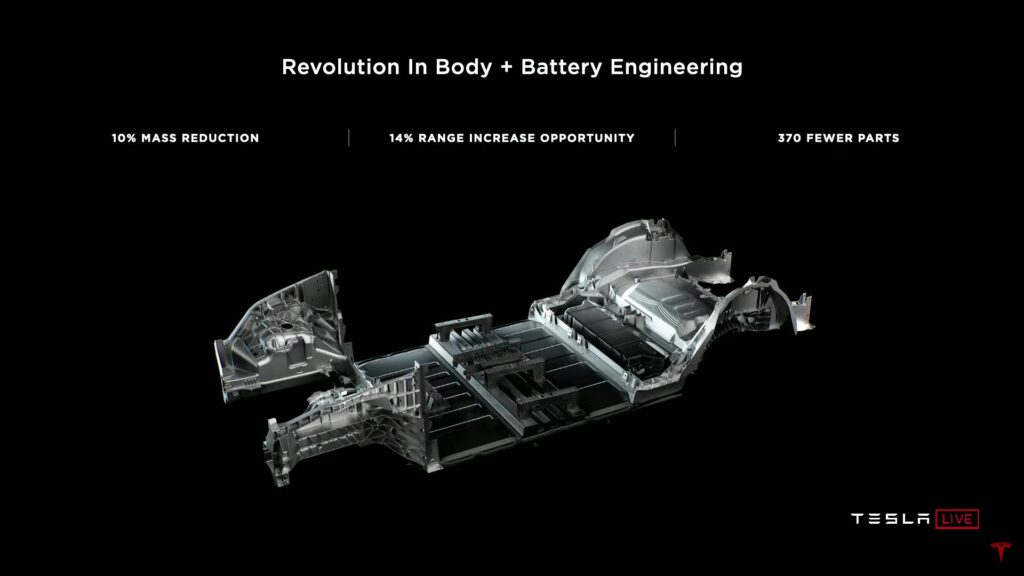

Revolution in Body + Battery Engineering

Tesla Battery Day

Tesla Model Y and Model 3 have the most advanced battery packs the automaker has put in production yet. But Tesla is aiming to take it to the next level in its near future battery pack innovations.

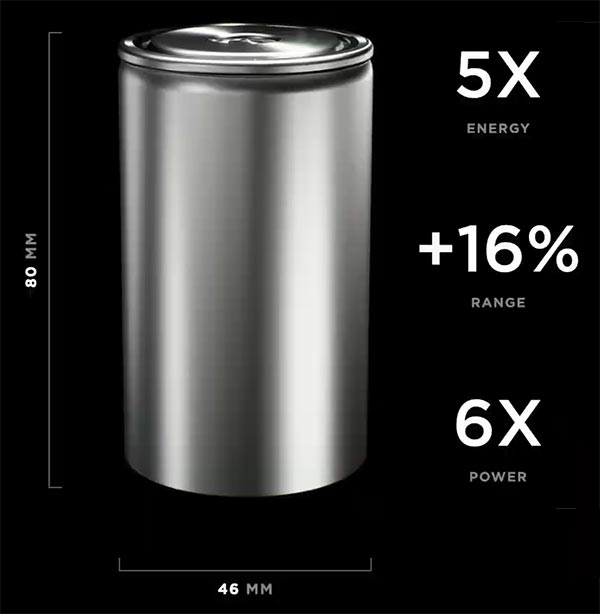

The current batteries also provide a low center of gravity and structural rigidity. The future batteries, as we can see in the above presentation slide by Elon Musk, getting rid of the empty space and filling them with Tesla’s new 4680 cells (illustration below).

This new cell is more than double in diameter and 10mm taller in length compared to the currently used 2170 cells. With 5X more energy, 6X more power, and a +16% range, the next-gen 4680 cells, and structural battery pack are going to give Tesla a distinct edge over other electric vehicle manufacturers.

The use of structural batteries according to Tesla will reduce 370 parts currently in use and has a potential of +14% range gain and 10% mass reduction.

A structural battery allows the cells to be comparatively closer to the center of the car, this phenomenon reduces the probability of a side impact potentially reaching the cell. This also improves the polar moment of inertia, as Elon Musk described in his presentation.

The net result is improved handling and safety of the car. Tesla yet again promises to boost car safety to another level while already building the safest cars on the planet.

Related: Tesla unveils the structural battery pack at Giga Berlin

Let’s watch Elon Musk deliver the Structural Battery presentation on Battery Day. I have set the video to start at this specific segment for ease of reaching the point.

Stay tuned for more, follow us on Google News | Flipboard | RSS (Feedly).

Related Tesla Stories:

- Tesla starts rolling out FSD v14.2.2.3 (2025.45.8), official release notes

- Tesla (TSLA) to discontinue FSD package from Feb, only subscriptions will be available, Musk announces

- SpaceX to produce ~10,000 Starships per year at Starbase, says Elon Musk, Gigabay construction update (video)

- Tesla offers a 5-year, Unlimited KMs warranty on 2026 Model 3 and Model Y in Australia and New Zealand

- Tesla Cybercab has so much that’s not obvious on the surface, says Elon Musk

- Cop pulls over a Tesla Model Y Juniper because of its taillight design