Vehicle teardown expert Sandy Munro undertook the project of tearing down a Tesla Model Y more than a month ago and has released 40 episodes showing component-by-component analysis in each episode.

In the final episode of this Model Y teardown series, Sandy Munro gives 10 key takeaways from this in-depth analysis (Ep 40 video at the end below).

Jump to the desired section:

- Mega Castings

- Improved BIW

- Fit and Finish

- Wiring Architecture

- Heat Pump & OctoValve

- High Voltage Battery Enhancements

- Injection Molded Headliner

- Commitment to Commonality

- Front Induction Motor

- Tesla FSD Computer

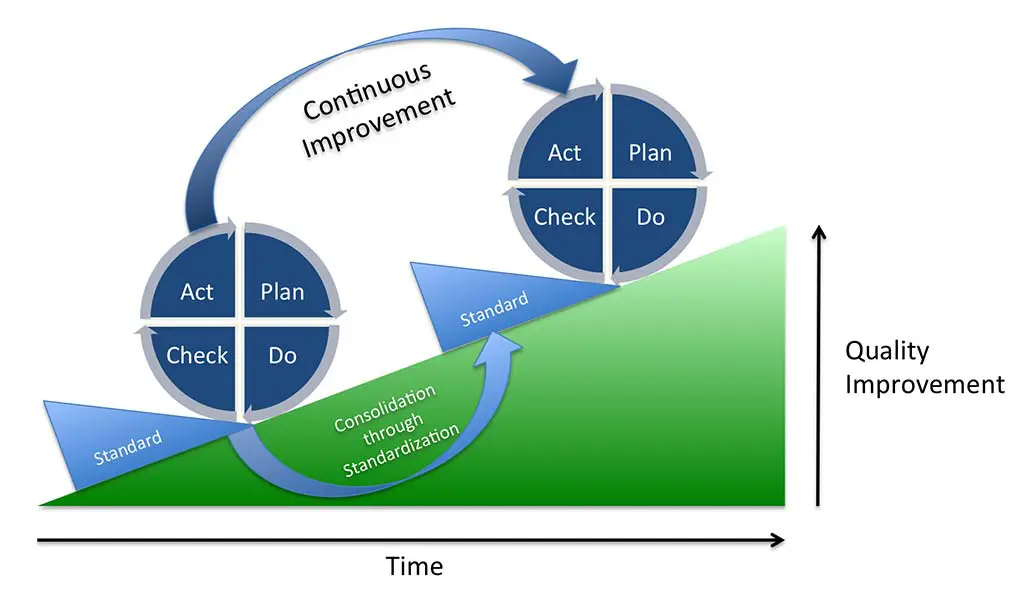

Continuous Improvement

According to the Munro & Munro Associates analysis, Tesla has integrated the approach of ‘Continuous Improvement’ into the company’s manufacturing cycle. This work ethic was actually the invention of a phenomenal American engineer Dr. Edwards Deming, therefore this approach is also called the ‘Deming Cycle’ or Plan-Do-Check-Act (PDCA).

Munro says that this is the opposite of the ‘Continual Improvement’ cycle that the other OEMs are practicing, a manufacturer waits for the launch of the next model/version of the product to be brought to the market in order to apply the enhancements in batches — but Tesla continuously keeps pushing the quality and innovation updates to the vehicles that are already on the assembly line.

These guys here are doing something that’s a step-change beyond everyone else, and this car should be a wakeup call for anyone who’s manufacturing anything, regardless of whether it’s a cellphone or a car or an airplane or anything in the marketplace.

Sandy Munro

Tesla’s continuous improvement cycle is also imminent in its over-the-air (OTA) software updates that constantly improve existing features and introduce new ones from time to time, competitors have yet to come up with a similar solution in this arena as well.

Some examples of continuous improvements in the past for the Model S and Model X have been the introduction of the Raven Drivetrain and the Raven Air Suspension to enhance the cars’ efficiency and performance.

#1: Mega Castings

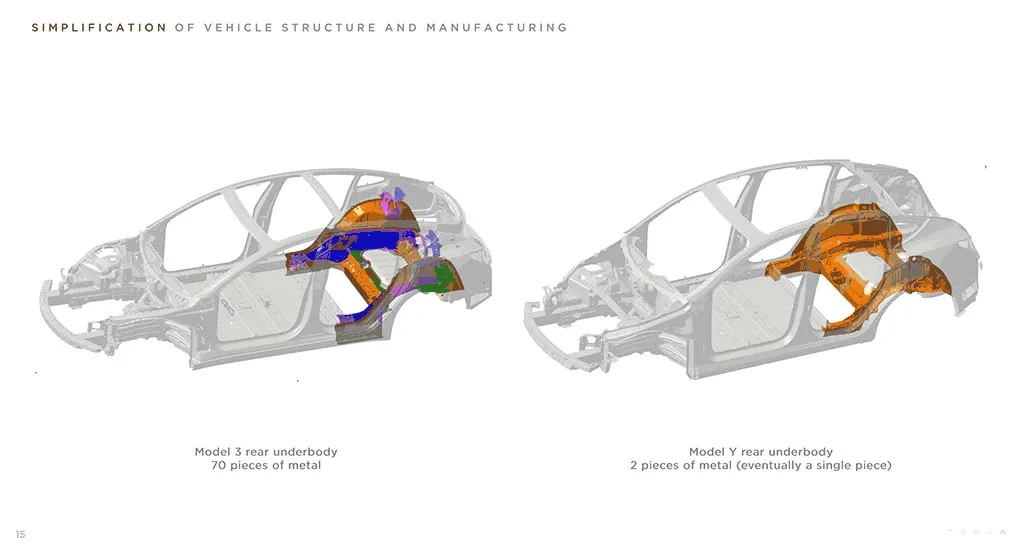

As time goes by, Tesla is using fewer and fewer parts to cast the body structure of their vehicles, using large single pieces to create the car’s structure and ultimately transitioning to the unibody structure as we saw with the Cybertruck exoskeleton and a patent filed by Tesla last year that shows a giant casting machine making the entire body of the car in a single piece and one go.

The rear underbody of the Tesla Model 3 is comprised of 70 pieces of metal and for this reason, became too complicated and needlessly expensive to build. The engineer responsible for this mess had already been fired by Elon Musk last year before Munro reported the problem to the Tesla engineering team.

Learning from this mistake, the Tesla Model Y’s rear underbody consists of only 2 parts, and in the next cycle of improvements Tesla aims to only have one instead of two, Tesla recently released the above figure showing the difference between the Model 3 and Model Y rear underbody casting.

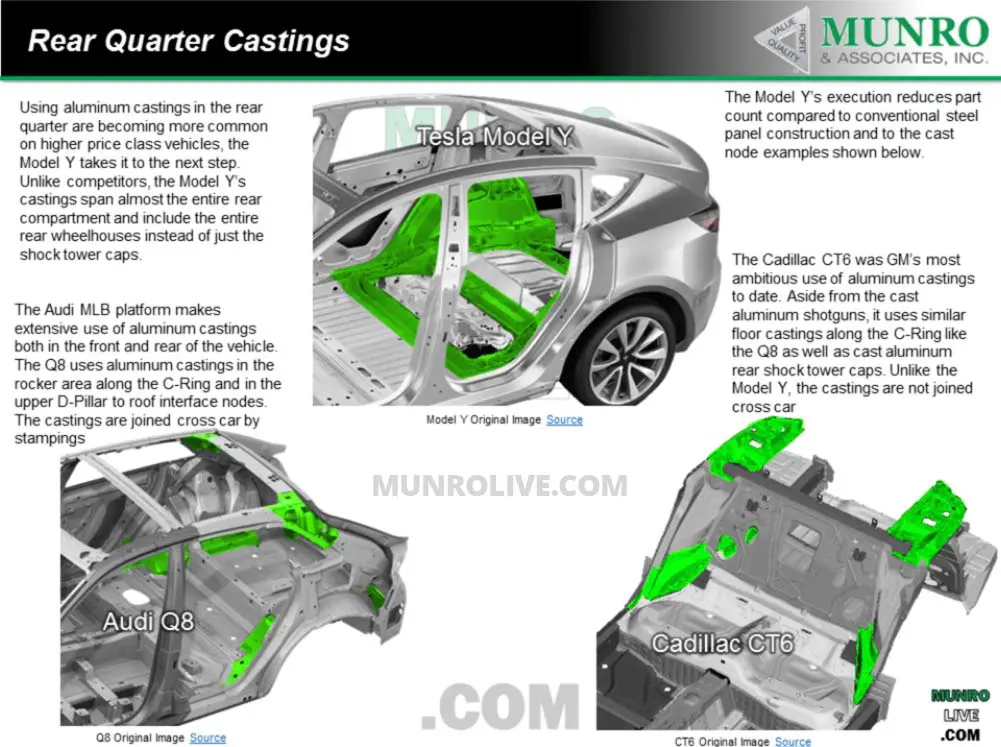

Munro & Associates also compared the rear quarter castings of the Model Y with the higher-priced Audi Q8 and Cadillac CT6 in their report, Fig 1.2 below shows the visual comparison of the castings and the amount of aluminum used in the rear part of these cars.

Munro’s report says:

Using aluminum castings in the rear quarter are becoming more common on higher price class vehicles, the Model Y takes it to the next step. Unlike competitors, the Model Y’s castings span almost the entire rear compartment and include the entire rear wheelhouses instead of just the shock tower caps.

Gradually when multiple castings are combined, it escalates the tooling cost, and the physics involved gets more complicated — but Munro thinks Tesla will be able to handle this as the automaker is creating the aluminum in-house and developing the material science required to achieve this goal.

#2: Improved BIW (Body In White)

Sandy Munro hasn’t been a big fan of the Tesla Model 3 BIW and has been critical of how it has been put together but when he compared it to the Tesla Model Y’s body in white.

Tesla has taken the right steps in the right direction when it comes to welding, riveting, bonding, and clinching together the entire structure. Munro tried to find the faults with a hawk’s eye but was able to find very few of them compared to the Model 3.

He recommends watching Ep 11, Ep 14 (above), Ep 15, Ep 33, and Ep 37 for a detailed look at this aspect of Model Y manufacturing.

#3: Fit and Finish

Although Tesla has taken a significant leap forward in terms of fit and finish compared to the Model 3, the analysis by Munro suggests that Tesla still needs to address the paint quality and panel gaps issues, especially on the rear end around the taillights.

#4: No 100 meters Wiring Architecture

Hopes were high that the Tesla would implement its revolutionary 100m wiring architecture patent in production Model Y cars but when Sandy Munro disassembled the wiring system, he found out that there was no major reduction in the wiring length but the application of the wiring system was found to be better than the implementation in the Model 3.

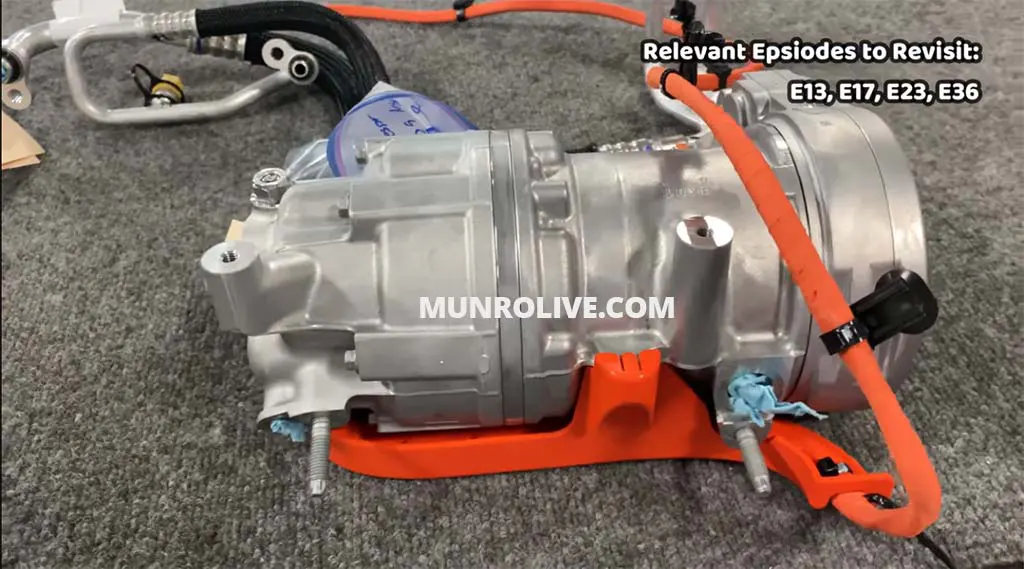

#5: Heat Pump & OctoValve

As Elon Musk said on Twitter:

Model Y heat pump is some of the best engineering I’ve seen in a while. Team did next-level work.

The heat pump and rear body castings are a step beyond

Elon Musk / Twitter

Sandy Munro’s analysis concludes that the Model Y heat pump and OctoValve are a work genius, the integration of the heat pump in the Tesla Model Y instead of a classic compressor helps in increasing the car’s HVAC system’s energy efficiency, which will also give the Model Y an edge in cold climates in warming up the cabin and the battery pack, Elon Musk further explains the heat pump in the following tweet:

Yes. PCB design techniques applied to create a heat exchanger that is physically impossible by normal means. Heat pump also has a local heating loop to spool up fast & extend usable temperature range. Octavalve is pretty special too. Team did great work. No credit to me.

#6: High Voltage Battery Enhancements

Sandy Munro’s Model Y teardown reveals that the high-voltage system of the vehicle was also enhanced and multiple ways, even the cells have improved.

Munro suspects that the battery chemistry of the Model Y cells is different than the Tesla Model 3 battery pack cells the firm had previously analyzed, the new chemistry according to him should have reduced the cost of cells and ultimately of the entire pack.

The battery pack of the Model Y is also more cost-efficient as Tesla has successfully removed the unneeded objects like excess tape, and fasteners, reducing the amount of potting materials (used for electric insulation, heat, shock, and corrosion protection, etc.), eliminating more than 50% of the temperature sensors — while still maintaining the full functionality, some excellent stuff here by Tesla engineering!

#7: Injection Molded Headliner

In contrast to the Model 3’s glass fiber compression-molded headliner, Tesla opted to use the injection-molded plastic construction to create the expansive Model Y headliner — this approach also reduces the amount of time, effort, and the number of components in manufacturing and installing the headliner compared to the conventional methods.

Like the body structure castings, the Tesla Model Y headliner is also molded in just 2 pieces, although this method increases the initial tooling cost but justifies when the vehicle is produced at scale, saving cost and time on the product rather than the machines that make it.

#8: Commitment to Commonality

Long before the Tesla Model Y was launched, Elon Musk said that it would share around 75% of the parts with the Tesla Model 3 — this enabled the automaker to make the Model Y production streamline far easier and faster than it initially took for the Model 3.

Munro found out that both vehicles share a lot in common but he has not yet come to the conclusion that the exact ratio of the parts sharing is 75%. Even the seats are common throughout the entire lineup from the Tesla Model S, 3, X, and Y as we can see on the seat label in Figure 8.1 below.

Other major components of the Model Y and Model 3 are pretty obvious to the common user like the dash, screen, steering wheel, headlight, drive units, etc.

#9: Front Induction Motor

Since Sandy Munro is comparing a 2020 Model Y teardown to the Model 3 teardown he performed in 2018, the improvements he discusses for the front induction motor must have been transitioned to the new Model 3 motors as well.

In the new front induction motor of the Model Y and most probably for the Model 3 too, Tesla has substituted the expensive vacuum brazed copper rotors with a die-cast aluminum assembly — cost reduction yet maintaining the functionality.

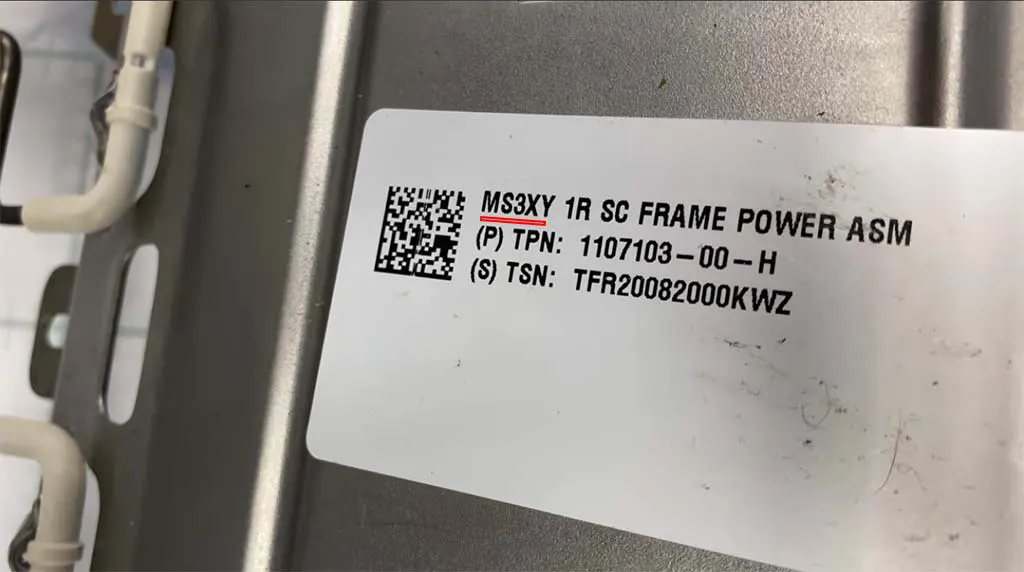

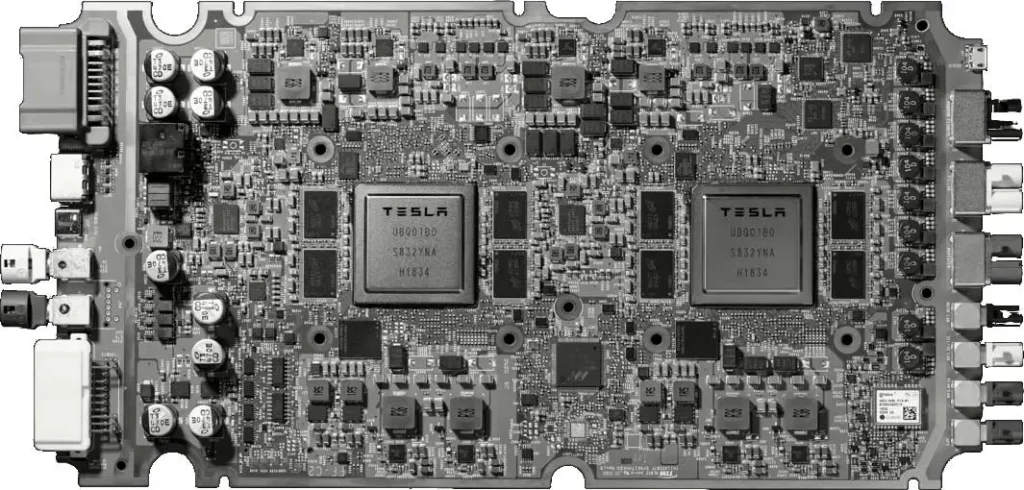

#10: Tesla FSD Computer

The major takeaway for Sandy Munro from the whole Model Y teardown is the Full Sel-Driving (FSD) Computer which is currently at version 3.0 and at the time he did the Model 3 teardown the computer or hardware suite was at version 2.5.

Even at that time, Munro said that this circuit board seemed like it was built for an F-35 fighter jet, and at the time Tesla was using the Nvidia self-driving supercomputer but they had already started building their own FSD chip which was way beyond anything the Nvidia / HW 2.5 computer is capable of.

The FSD Computer (HW 3.0) was unveiled at the Tesla Autonomy Day last year, where the Tesla Director and chip designer Peter Bannon told the story of how he and his team went on the journey to develop the world’s fastest self-driving supercomputer.

Munro’s electrical/electronics engineering team is taking an in-depth look at the FSD Computer they fetched from the Tesla Model Y teardown job and we should expect some commentary from him on it sometime in the near future.

Stay tuned for constant Tesla updates, follow us on:

Google News | Flipboard | X (Twitter) | WhatsApp Channel | RSS (Feedly).